TS Hungaria Kft. has one of the most advanced wheelset maintenance centres in Central and Eastern Europe. In our workshop, the most modern technology is combined with the highest level of expertise and the unique experience of more than a century and a half. We can also satisfy the unique needs of our partners, using sophisticated logistics solutions and component markings. This is how we try to meet all the requests of our customers.

During the repair of wheelsets, we adapt to the needs of the customers and carry out the repairs and maintenance in accordance with the specifications requested by them. Our workshop also meets RIL and VPI wheelset repair standards. It is also thanks to this that our customers include Rail Cargo Hungaria, Rail Cargo Austria, GATX, ERR, ETS and Atir Rail.

We can carry out all levels of repairs, with impeccable quality, whether it's a visual inspection or re-pressing the wheelsets. We can keep the agreed deadlines with 98% accuracy, thus achieving the satisfaction of our customers.

In our factory, we use several types of automatic equipment, which make work easier, ensure accurate measurement results and reproducible, consistently high, impeccable quality.

By using our computer-controlled wheelset processing machines, we fully comply with the safety regulations for wheelsets, taking into account both the RIL and VPI regulations.

In 2023, two painting-drying cabins were put into operation, which make it possible to paint wheelsets in suitable quality and under suitable working conditions.

The units specially optimized for painting and drying were installed one after another, thus enabling continuous work, taking into account both painting and drying activities. A special track system has been installed in the cabins, which allow the wheelsets to be moved quickly and safely.

Thanks to these developments, we can fully coat up to 24 railway wheelsets per shift, and up to 72 railway wheelsets per day.

Wheelset painting hall

Wheelset painting hall

Wheelset painting cabine

Wheelset painting cabine

Automatic wheelset pressing machine

Automatic wheelset pressing machine

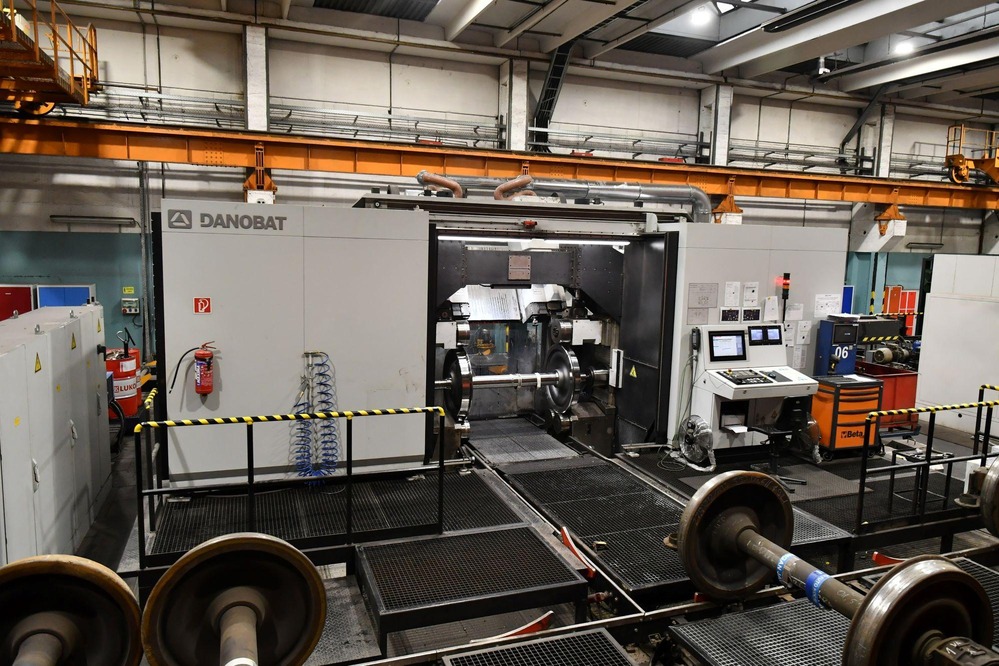

DANOBAT DPL-2600 Profile Lathe

DANOBAT DPL-2600 Profile Lathe

Danobat 2021 profile lathe

Danobat 2021 profile lathe

Automatic wheelset pressing machine

Automatic wheelset pressing machine

NCT BNC 40120 Lathe between discs

NCT BNC 40120 Lathe between discs

Ultrasonic washing equipment

Ultrasonic washing equipment

Automatic abrasive blasting equipment

Automatic abrasive blasting equipment

In order to preserve the condition, the raw materials and finished products are stored and delivered in accordance with the requirements.

Delivery on wooden pallets

Delivery on wooden pallets

Storage of wheelset shafts in the work area, waiting for machining

Storage of wheelset shafts in the work area, waiting for machining

In order to ensure quality requirements, we have the most modern material testing machines.

Automatic internal voltage measuring device

Automatic internal voltage measuring device

Automatic shaft and disc ultrasonic equipment

Automatic shaft and disc ultrasonic equipment

Magnetic particle test equipment

Magnetic particle test equipment